Deodorisation of cocao butter

Purpose of deodorization facility is to remove odor and to physically lower the amount of FFA (free fatty acids). This is made on high temperature and in deep vacuum. This system is easy to manage, maintenance and facility is long lasting.

Cacao butter is heated to 80°C in reception tank and then it is transported in deodorization system in which there are heat exchangers, pumps and deodorization “floors”. FFA evaporate at 170°C and with deep vacuum (3 mbar aps pressure). FFA steam is caried with stripping steam. FFA steam is then condensed with cold liquid faze, recirculated and then ejected out when there is high level alarm in reception tank. Temperature is achieved with 3 heat exchangers (HE1, HE2 and HE5). Final product, deodorized cacao butter is cooled down with 2 heat exchangers (HE1 and HE3). Beside removing FFA under 1,75%, butter is odorless (deodorized). Energy saving is maximum with heat transfer when heating and cooling in heat exchangers (using own butter heat). Vacuum is achieved with 4 ejector system.

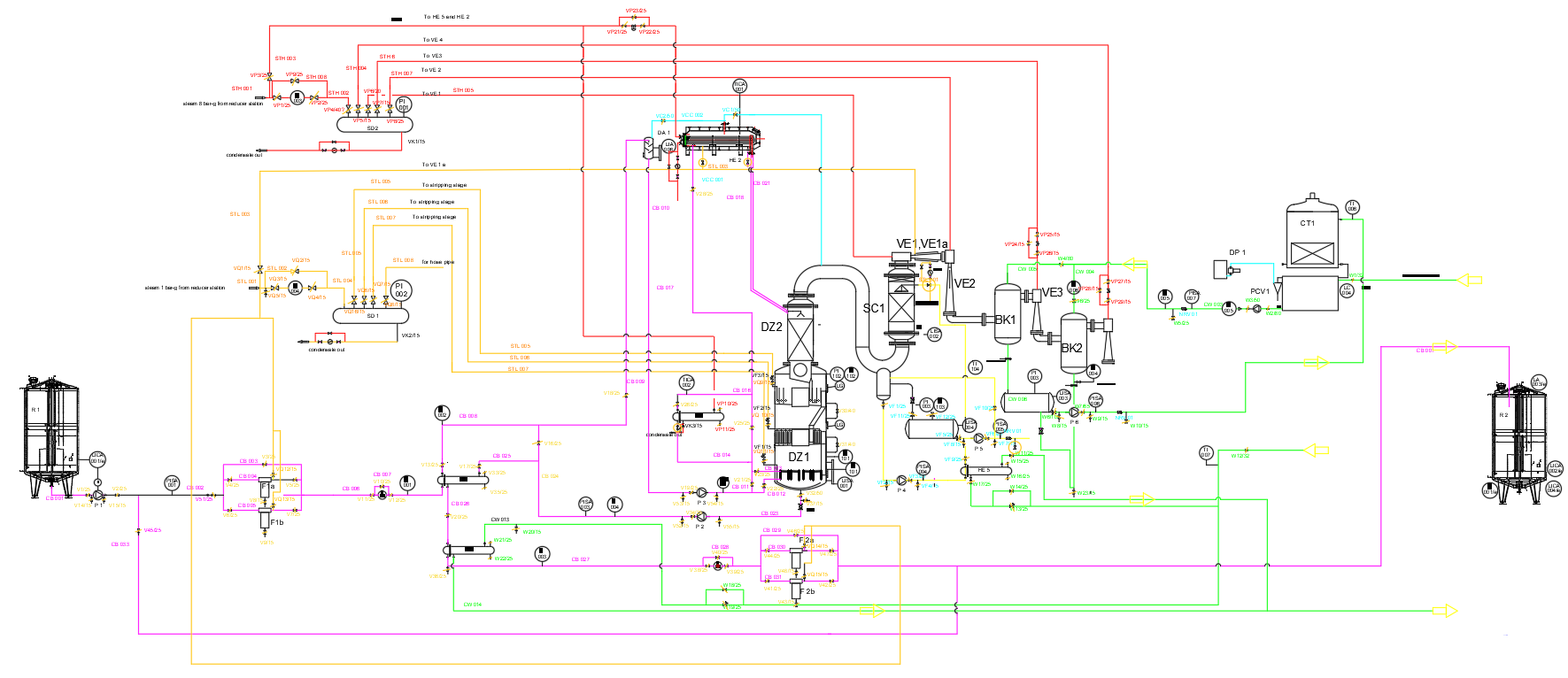

Schema of deodorisation

© 2022 Dynamic Elchem. All rights reserved